Our Case Studies

Foundry Tooling Case Study

About The Project

The Challenge

Our client, a sand casting foundry had an aluminium casting that required a complicated mould assembly within an aggressive timeline.

We met the client and had regular onsite meetings with the key stakeholders including the project manager and technical metallurgist team. These 'challenge' meetings ensured that everyone was aware of the task in hand and the key objectives that needed meeting to ensure the optimum casting for the end customer.

What we did

Plan, Design, Review......and Repeat..!

During the 4 week project our design engineers continued communication with a range of stakeholders via onsite meetings and conference calls to ensure that the issues were ironed out and decisions made.

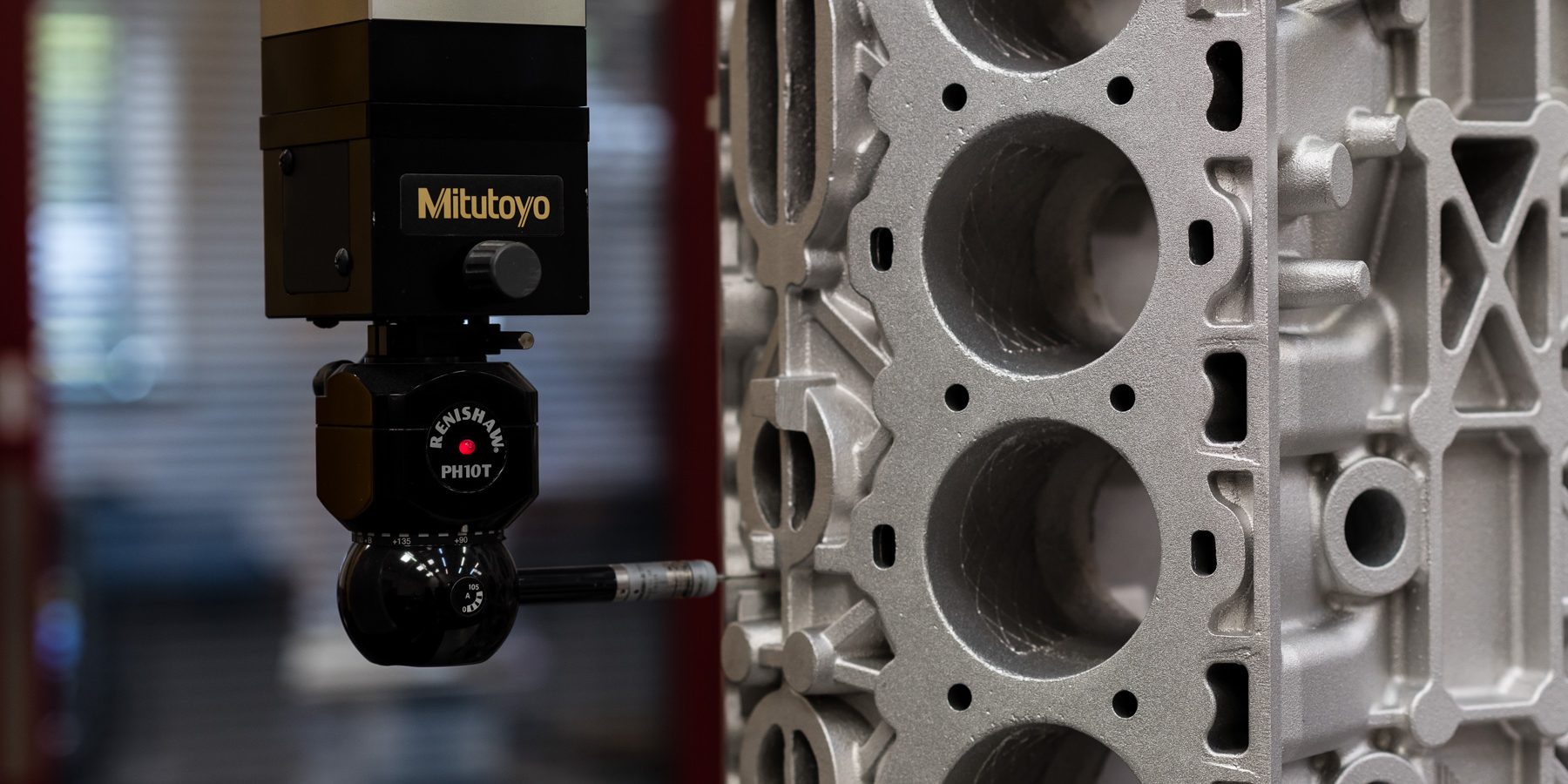

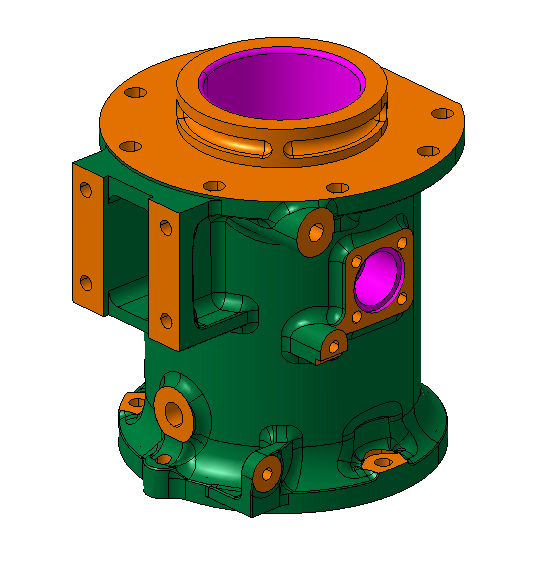

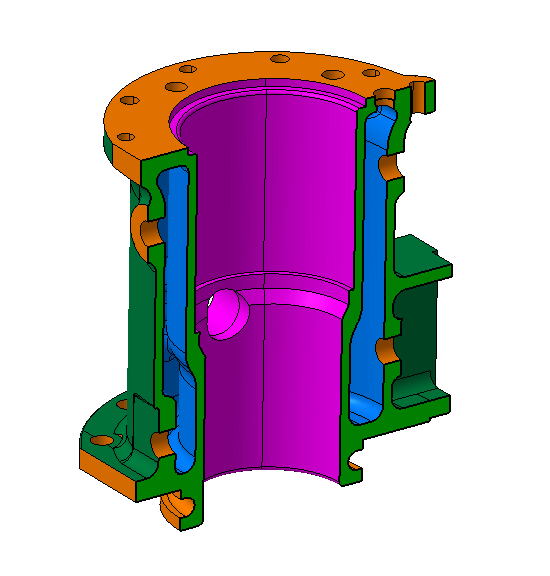

Due to the complex casting methodology, multiple casting simulations were required during the design process. At each simulation we were able to feed the changes into our models. Due to the parametric nature in which we work we were also able to fast track updates to the original cast models.

The results

On Time Delivery of 24 Piece Tool

The client recognised that the job was huge in scale and complexity. Their Engineering Director was really impressed with the project outcomes and the effort from the whole tooling team.

Paper to CAD Case Study

Our client required a boat cylinder head modelling from a 2d drawing. Our design engineer was able to quickly interpret the data and provide the .stl files back to the customer.

3D Design and Print Case Study

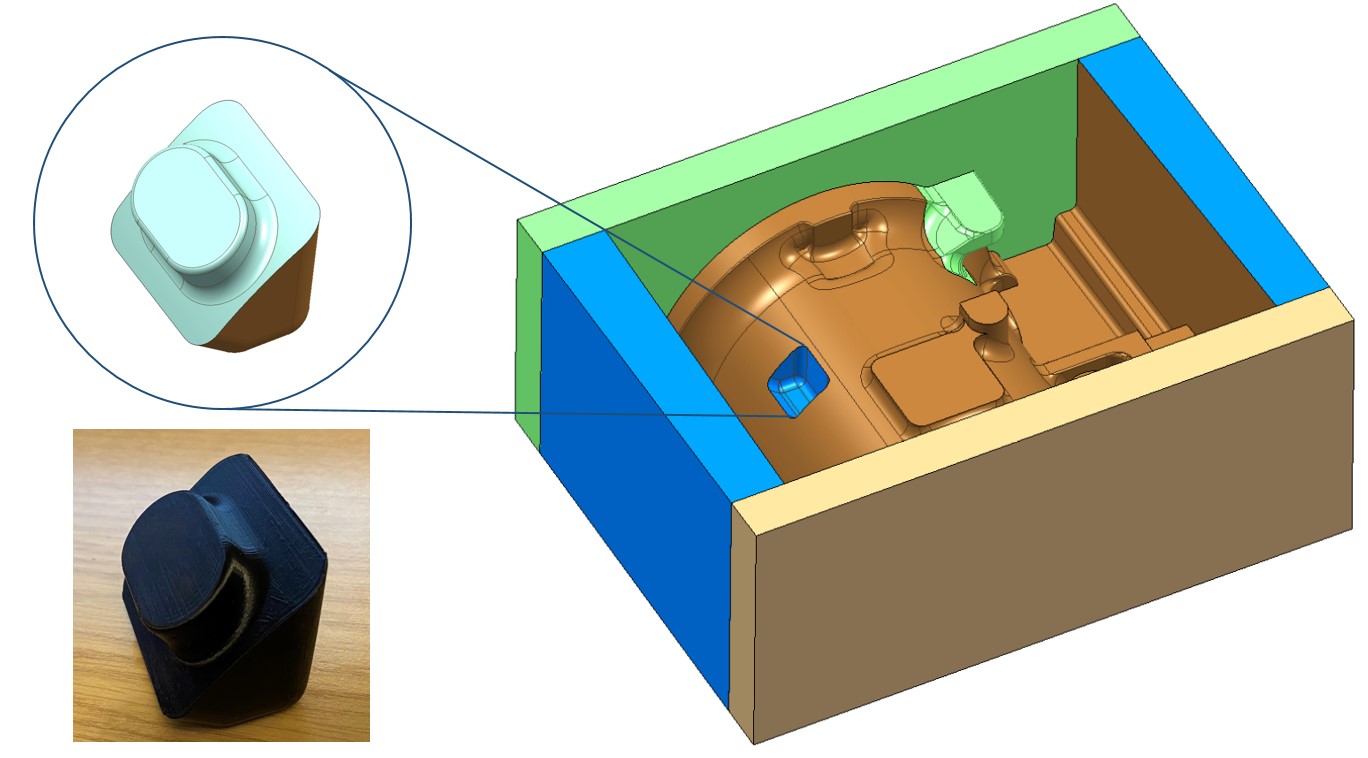

Tooling Loose Pieces

For this project the component data was provided by our customer. We then used this data to design the 3d mould pack and all the associated tooling to produce the sand moulds. The design was supplied to our customer to CNC machine and finish. In order to reduce CNC cutting hours/costs we provided the 3D printed loose piece.